VW Engine Internal Upgrades

What upgrades can be made to engine internals?

There are significant advantages to be had by upgrading the internal engine components. These upgrades include:

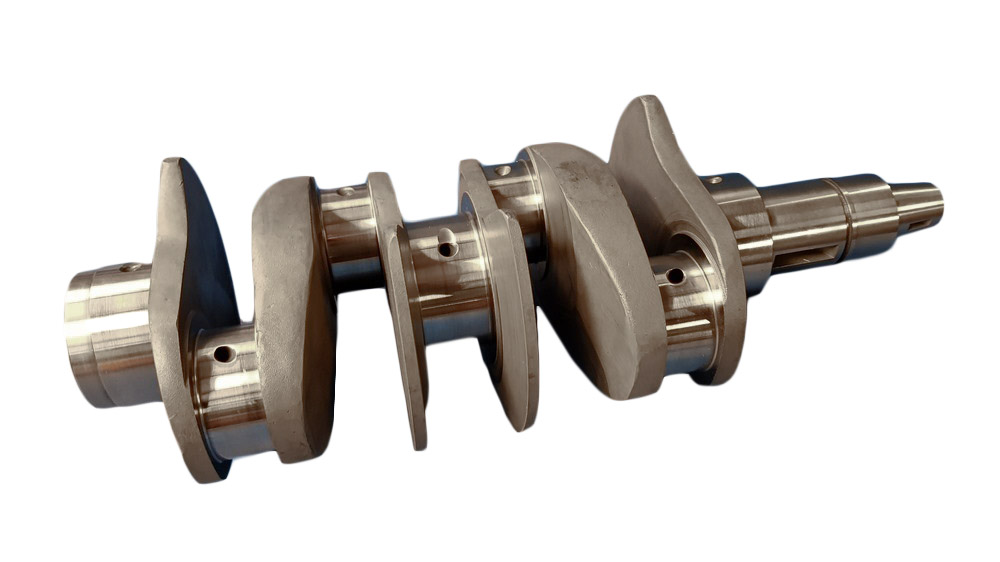

- Forged / stroker crankshaft

- Forged conrods / optimised rod length

- Forged / big bore piston and cylinders

- Camshaft Upgrades

- Cam follower upgrades

- Valvespring upgrades

- Rocker upgrades

- Compression ratio modification

How do upgraded engine internals benefit me?

The advantages of uprgrading internal engine components fall into 2 main categories:

- Engine durability or strength

- Performance

Upgraded component materials, such as the use of forged pistons, conrods and crankshaft are designed to increase the amount of stress that your engine can withstand. In a high performance engine, the increased RPM capability and amount of torque produced can exceed the design tolerances of individual components which will lead to component failure.

It is therefore essential that as performance is progressively increased, the strength of the individual components must be able to withstand the additional stress.

Upgraded internal components can also be designed for a performance increase. Stroker crankshafts and big-bore pistons & cylinders increase the displacement of your engine. Through the use of these components and our in-house engine machining capabilities, we are able to build engines in excess of 2700cc for an enormous performance increase whilst retaining drivability.

An upgraded camshaft has the potential to greatly increase the engine power, but if the incorrect camshaft is used, low end power and drivability can be compromised. The aggressiveness of the camshaft must be carefully considered and matched to the rest of the engine. We have unfortunately seen "street" engines that have been fitted with excessively large camshafts and are poorly matched to the engine. These engines can produce a reasonable peak power number on the dyno sheet, but low end torque has suffered and the overall driving experience is very poor.

When choosing a camshaft, we carefully consider the customers requirements, engine displacement, compression ratio, intake, carburettors / injection, exhaust, valvetrain, internal engine geometry and more. With over 35 years of experience with VW performance, we know the perfect combinations that will give you the power you desire, whilst maintaining engine durability, longevity and drivability.